S P R A Y F L U S H

S P R A Y B U I L T and S P R A Y H E A T

Fresh water freely falls to sustain life on our planet spinning endlessly through time and space, yet most humans will never know the joy from having their very own home.

Overview

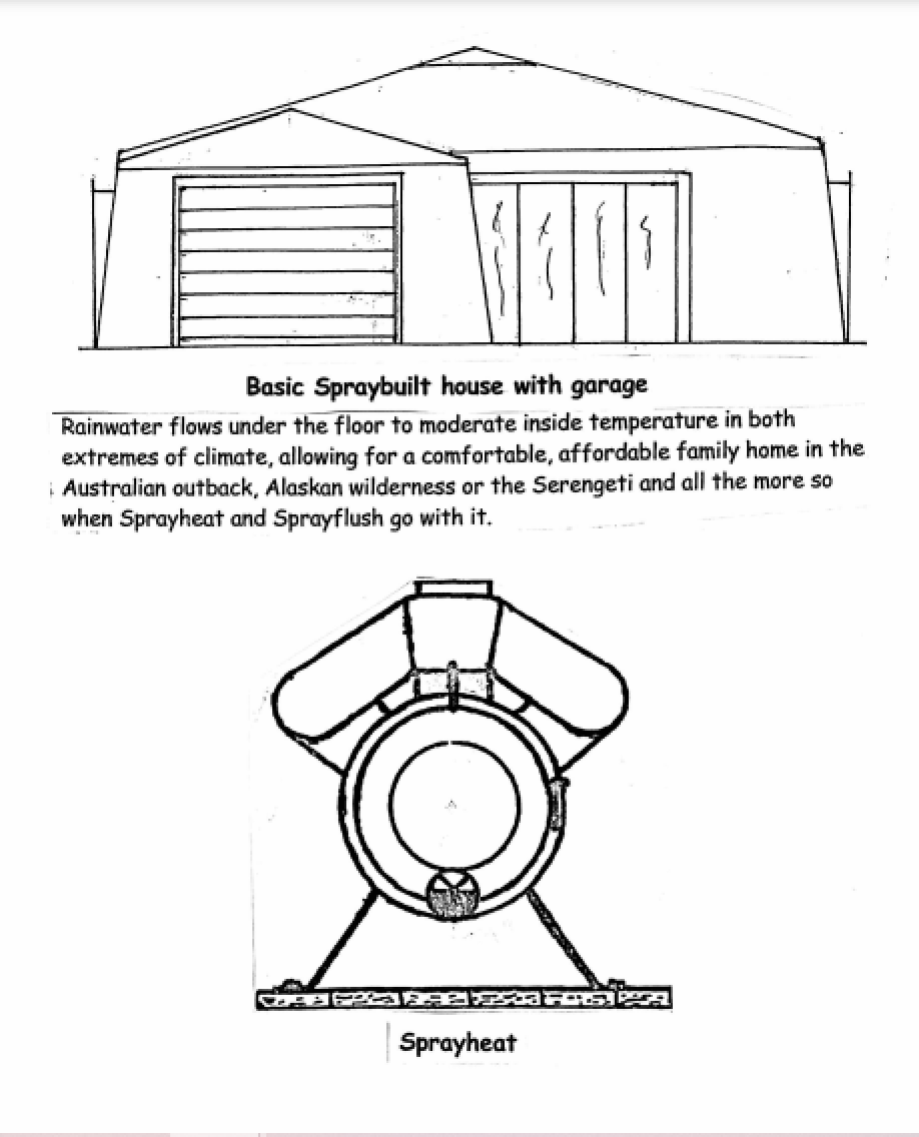

Focus during Spray technology development was on families having their own homes around our amazing planet with acceptance of it only coming out of necessity. However, imagine living ‘off grid’ in a ferro-cement Spraybuilt home with your own water, solar energy and methane.

Sprayheat is non-polluting and burns wood coal or methane with seasoned wood gathered in summer sufficient for all your winter heating. Your Sprayflush toilet flushes by foot and uses a minimal volume of air saturated water to flush catalysts to a digester to produce methane from grass out of your lawn mower catcher.

Your ranch sliders foot adjustable vents and apex vent control gives fresh cool airflow without an air conditioner, while soft light reflected off the ceilings adds much to a stress-free life, as does having your interior walls where you choose. Nice knowing also that Spraybuilt unbolts to insert ‘modules’ to expand out for a single story or up for two, and that your grey water flows to an in-ground control tank to automatically flow through soak hoses onto your gardens.

Using ferro cement as a building material is not new as high-rise office blocks use it for strength and low cost, and the Spraybuilt variation of sand and cement plastering is used to build transport haulage barges throughout Asia and ocean going yachts in New Zealand, but the Spraybuilt variation in design may never be generally used for homes due to its ‘low cost and permanent strength’.

Spraybuilt can be built on-site in one piece or as modules in a factory and assembled on its foundation. The outer area of a modules shape is welded steel plate and acts as a rafter, with the inner area having horizontal purlins with woven stringers overlaid with galvanised wire mesh and plastered with a sand and cement mix. Flexible ceiling props are used during curing to give the ceilings a 150mm arc over 3.7 metres.

The first part of the Sprayheat flue from the firebox is horizontally over a round firebox as a saddle with two levels within it, that gives instant maximum warmth in a room as it rises to the ceiling to circulate throughout the home. The ash tray slides under the fuel basket and water heating coil with the damper fully open on the initial burn and progressively closed as embers are seen, as the ‘run’ damper on the bottom of the door controls warmth levels. Sprayheat can heat 300 litres of water in 15 minutes in winter.

Sprayflush technical 1 Sprayflush grey water control 2 Sprayflush story 3 to 6

Sprayflush video 7

1 Sprayflush does not have a cistern but does have a seat that lowers itself on full flush, by one seat hinge connected to a floating lever fixed to the rear of its frame and a modified screen door closer on the same side next to the flush valve lever. Lifting the seat draws air into the pump as a swing arm drops into a notch on its inner rod to hold up, while the flush valve lever pushes it out on full flush to lower on a cushion of air. There is a brush and container under the seat that is readily accessed by lifting the seat and a hinged lid that stays open by magnet, which closes as the seat goes down. There are three toilet rolls stored in an upright column each side of Sprayflush behind the bowl, and held in place by their own weight standing in a shallow channel for ease of lifting out and staying open.

Sprayflush water flows directly to the flush valve while pressurising a reversible pipe containing a perforated tube of blue disinfectant, that enters the wall spray valve when it opens to activate the wall spray jets under the seat, and does so from a link to the flush valve just before full flush and just after.

A touch on the flush valve prior to a bowels flush wets all surfaces for a clean flush, then again on release of the flush-bar that leaves a residue of disinfectant in the lower bowl. The flush valve also opens and closes the mechanical airlock.

The lower bowl holds a 100mm wide spin chamber with two opposing water jets hitting their own floors, with the rear floor higher to create a slit to prevent disruption from the jet below. Both jets are set at 25 degrees vertically to the floor and horizontally to the slit, and push waste against and under three deformed rings as a cage using gravity and centrifugal force, and is simply removed and replaced by a knurled bolt behind the bowl and accessed by lifting out a toilet roll store. The jets are 3mm chrome ball point pen nib covers glued into 15mm brass elbows and used for their internal shape and high energy spread from 65 psi water pressure. The nib covers have six internal blades to keep the pens ink-tube aligned with the hole it goes through prior to writing. For Sprayflush, those blades stop the water creating a vortex and loss of energy.

Both jets create a fast spin of air saturated waste and catalyst through the airlock for added biodegradable product in its digester, with a bowels flush taking five seconds and water use under a litre, while a urine flush is direct and instant requiring only a brief spin and wall spray rinse and water use to quarter of a litre. House water supply connects to Sprayflush first.

2 Sprayflush grey water re-direction control consists of two 200 litre drums placed horizontally beneath a lawn with a 200mm wide pvc pipe vertically beside them and linked with their floors on the same level, with the top of the 200mm vertical pipe being at waist height. Grey water flows in the top cap of the 200mm pvc pipe through a stainless steel gauze into a dish at the top of a 50mm flood tube, with a 20mm pvc Tee pipe inside it. The foot of the Tee has a fresh water activated jet aimed up it to a ball valve each end of the arm of the Tee with a 50×5 mm pointed blade of clear perspex in the top of the cap as a grey water gauge.

In use, grey water flows in the top to fill the flood tube which flows up the 20mm pvc Tee pipe to the ball valves if they are open, to flow onto gardens and continues by siphon. If the ball valves are closed and the drums full, grey water flows to the Sprayflush digester outflow junction and under gardens and lawns. Grey water can be used randomly by activating the fresh water jet in the foot of the Tee.

3 The Sprayflush story started in 1996 by a fifty year old man who has always had a fascination for planet earth and all life upon it. He was born into a highly dysfunctional family at the end of the second world war and was ostracised to the point of being thrown across a room against a wall before he could walk, and later sabotaging the front brake on a bike to be thrown head first onto the road at the bottom of a hill. I write this to stress the point that Sprayflush did not come from a University or a profit driven research and development company.

He was often sent from his home to be with good people who taught him many things other children may only imagine, but his maternal Grandparents taught him the most about life and our earth with its seasons, especially natural evaporation, gardening, composting and recycling.

Over-use of pain killers from childhood and self medicating through his teenage years led to alcohol addiction which drove him to seek help from a rehabilitation home, where he learnt how to live on ‘the 12 step program’ and has been clean and sober since January 13th 1991.

He was under a Doctors care for depression, cholesterol, diabetes, and back and neck pain during 1996 and had told his Doctor he had been having bad headaches as he feared he would lose his taxi license in telling the truth, which was going blind while driving a taxi down a fast freeway. Being in the left side lane enabled him to drive into an empty truck stop using his last memory of it. It was a Friday afternoon with his sight returning while waiting for a response from the busy query operator.

The Doctor sent him for a brain scan and a neck x ray with his verdict being that his neck was comparable to a very old man, and must have played a lot of rugby union football and that the brain scan showed he must have been in a very serious car accident very early in his life.

4 He would sometimes throw bits of bread and honey to a couple of Lorikeets standing on the path outside his home when having breakfast after driving a cab all night, but while off work had not seen them for a while and realised how fed up with life he was and needed to make changes, which he did by disposing of his Doctors medication and having a smoke and going to bed.

Sleep didn’t come easy when Martha his Grandmother came into his thoughts and he started thinking about his life and remembering statements from ‘rehab’ such as, “one who forgets their past have the burden of re-living it” as well as all that his Grandparents had done for him along with his Auntie Blanche and Uncle Billy. His Grandmother Martha was a Seventh day Adventist and knowing how he hated using the drum toilets at that time, showed him how the ancient Israelite’s had to go to the toilet in the wilderness after escaping slavery in Egypt (Deuteronomy 23:12) So Gods advice for their continuing health was to bury their bowel waste in the earth.

His Auntie Blanche and Uncle Billy always treated and spoke to him as an adult and was often taken on walks through the bush teaching him safety, and how to gather and bundle seasoned wood for home heating and cooking, but remembered the most was the taste of clean fresh cold spring water bubbling out of the ground.

After many hours of remembering the good people who were always there for him, he thought of the misery in his own home and the filthy and indescribable smell of drum toilets and rapid progress to the first water flushing toilet, that used at least ten litres of water to flush to an in-ground vented septic tank with its excess outflow going under lawns.

On a fast panicked escape from his dad one day, he dropped to the lawn too soon to slide under the house to a hideout he had previously found that was a three walled brick foundation for the fire place and chimney above. Waiting in the dark for his eyes to adjust, he realised he was saturated in a mix of the families bowel waste and urine. Within a few years the local council dug up roads to install pipes in the town to take expanding sewerage volumes to a first ever treatment plant that turned sewerage into ninety nine percent water, apparently, then dumped into the river!

5 Waking up with Martha on his mind in his 25 foot caravan home saturated with tobacco smoke, he latched back both front and back doors and went back to bed when a dozen or so Lorikeets started flying in the front door and through his bedroom and out the back door, and didn’t stop until he got out of bed to get them some bread and honey by which time, they were all perched along his breakfast bar waiting to be served. They didn’t move at all except to eat as he gently placed honey coated bread in front of them. Martha and those Lorikeets set him on a pathway of peace and purpose and a distrust of Doctors and has not smoked another cigarette since. The next day he started his long and expensive and enjoyable search for Sprayflush. His caravan site was behind a friends house which had nice lawns and gardens and a garden area between his van and a river, so the first thing he did was to learn all about water and how to tame it under pressure.

He fixed an empty 60mm wide tuna tin in the floor of a 20 litre container fitted with two opposing 2mm water jets each side at 25 degrees vertically to the floor, and aimed half way between the tin centre and outside wall of the tin. He then glued a ring of pvc pipe around the top to force the water jets to spin and not go up, then filled the container and after it settled fully opened the ball valve with the water instantly turning and flowing over the sides like a hand basin with the tap left on. He was encouraged as with a hand basin the water energy is at the top but with this experiment, the combined energy of two small jets was pushing 20 litres of water weighing 20 kilograms over the top from the bottom. He knew he wasn’t wasting his time as he imagined larger jets on a larger floor area under containment rings shooting out through a 20mm exit tube.

He then used a conventional seat and lid to design and build a universal bowl, keeping in mind the walls will never be washed with water from a cistern, and the overall size would be universal in that Sprayflush would be compact enough to be installed in mobile homes and aircraft or anywhere humans go. It took him three days to flush bowel waste through a crude spin chamber with hack-saw blades cut into the wall to deflect water back into the path of the jets, and knowing where adjustments were needed, started on a digester and the grey water re-direction control system at the back of his van, with an easy slope to lawns and a garden.

He spent the next few years improving the overall Sprayflush performance while growing tomatoes cucumbers and lettuces using the ancient method, as after what his Grandmother had told him about the Israelite’s, had read of other cultures who designated areas to defecate into and cover over, then when the area was used up, another site was designated while the first one was left to ‘fallow’ for a Luna month before planting a food crop on. However, he used his modern method of growing his food above a slotted plastic drainage tube from his toilets digester.

6 He also buried bowel waste in a separate spot with a thin stake through it to recognise the exact spot later on. He covered it over and left it for a Luna month to find clean healthy natural earth so planted a lettuce seedling on top of it and ignored it until it was big enough for lunch. He still has a habit of sprinkling salt on lettuce leaves for a quick tasty snack.

He would often use the toilet in the house when Sprayflush was being modified and one day experimented by tightly taping a plastic sheet over the bowl and pushing the six litre flush button. The sheet bulged under pressure then burst the plastic sheet open on one side and pushed it over the bowl, which along with the dramatic noise and waste of water was encouraging, as using Sprayflush was fast and much quieter, with the same test sucking the plastic down two inches until release of the flush-bar.

He remembered what Mr Rolls from Rolls Royce fame wrote in his book on mechanical design that he had read during his teens which was “if it looks complicated it probably is and will always break down, but if it looks simple it probably is and never will”.

He had made a stainless steel mesh sieve to prevent blockages in his digester or so he thought, but after checking the sieve for small lumps buildup and finding none, had realised his spin chamber was not just breaking down bowel waste into a lumpy slurry, but the highly air-saturated water was boosting and expanding the natural bacteria within it to the extent that the digester at 20cm wide by 60cm deep made it easier and faster to liquefy bowel waste, while following urine flushes boosted its fast process with no variation in the time it takes between one person using it or the whole family, which makes it possible for families to enjoy an endless energy supply.

During the 1960’s he had read a book about a Catholic Nun living on a Pacific atoll during the 30’s who raised pigs and chickens and used their droppings to create methane, to burn through a low pressure gas ring to cook bacon and eggs on each morning. Also during that time he read an article in the N Z Herald about a man in the South Island of N Z using methane made from grass out of his lawn mower catcher and expected a follow up story but none was ever written.

So having a ‘chute’ at 45 degrees from the top of the digester that remains closed, but on filling the chute with grass from a lawn mower catcher and closed at the top, can be opened at the bottom to feed methane production without loss of digester pressure, for home space and water heating, cooking, and outside lighting and cooking in the barbecue area when entertaining.

Methane is a very light and abundant and safe gas with no smell, with digester pressure sufficient for it to drift through tubing to low pressure gas rings. Maximum methane output is above 25 degrees which can be maintained by a loop between Sprayheat and a hot water storage system in cold climates. Methane production is slowed or can be stopped if food is ever flushed.

For Sprayflush

Boyd Callahan. 24/09/2024

7 Video upload by 24/10/24